Comprehensive Equipment Lineup for Extrusion Blow Molding #

A successful extrusion blow molding operation relies on a well-integrated set of equipment, each playing a vital role in ensuring efficiency, quality, and productivity. Below is an organized overview of the key components included in a turnkey extrusion blow molding solution.

AUTO VACUUM LOADER

AUTO VACUUM LOADER

HOPPER DRYER

HOPPER DRYER

CHILLER (AIR COOLER)

CHILLER (AIR COOLER)

AIR COMPRESSOR

AIR COMPRESSOR

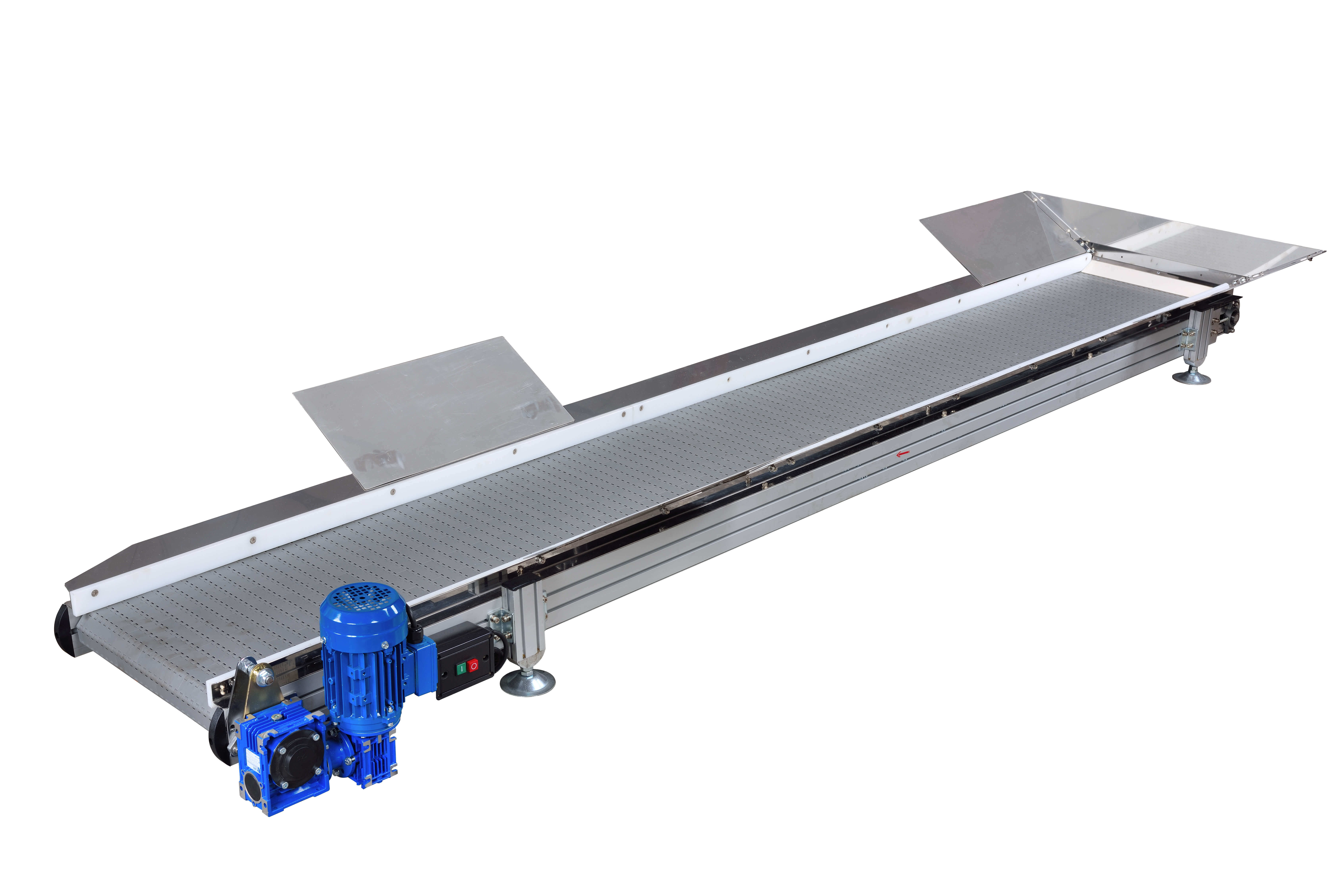

CONVEYOR

CONVEYOR

GRANULATOR

GRANULATOR

CONVEYOR FOR SCRAP

CONVEYOR FOR SCRAP

EXTRUSION BLOW MOLDING MACHINE

EXTRUSION BLOW MOLDING MACHINE

STORAGE TANK (FOR PIGMENT)

STORAGE TANK (FOR PIGMENT)

SEPARABLE AUTO LOADER

SEPARABLE AUTO LOADER

LEAK TESTER

LEAK TESTER

AUTOMATIC LABELLING MACHINE

AUTOMATIC LABELLING MACHINE

Key Equipment in the Turnkey Solution #

-

AUTO VACUUM LOADER

Automates the transfer of raw materials to the processing unit, ensuring a consistent supply and reducing manual handling. -

HOPPER DRYER

Removes moisture from plastic resins, which is essential for maintaining product quality and preventing defects. -

CHILLER (AIR COOLER)

Provides cooling for the molding process, helping to maintain optimal temperatures and improve cycle times. -

AIR COMPRESSOR

Supplies compressed air required for the blow molding process and other pneumatic operations. -

CONVEYOR

Facilitates the efficient movement of products and materials throughout the production line. -

GRANULATOR

Recycles scrap material by grinding it into granules for reuse, supporting sustainable production practices. -

CONVEYOR FOR SCRAP

Dedicated conveyor for transporting scrap material to the granulator or designated collection area. -

EXTRUSION BLOW MOLDING MACHINE

The core machinery for forming hollow plastic products through the extrusion blow molding process. -

STORAGE TANK (FOR PIGMENT)

Stores pigments or colorants, ensuring consistent color distribution in the final products. -

SEPARABLE AUTO LOADER

Offers flexible and efficient material loading, adaptable to various production needs. -

LEAK TESTER

Automatically checks finished products for leaks, ensuring quality and reliability. -

AUTOMATIC LABELLING MACHINE

Applies labels to products with precision and speed, streamlining the packaging process.

This comprehensive lineup is designed to support a seamless and efficient extrusion blow molding operation, from raw material handling to final product inspection and labeling.